A cozy family room, a home office, or even a guest suite are all functional spaces you can transform your basement into. These additions can increase the value and usability of your home. For new contractors and first-time homeowners in the US, knowing how much to frame a basement is crucial to avoid unexpected costs. Basement remodeling can lead to significant expenses if not planned carefully, which is why many contractors rely on a remodeling CRM to manage projects, clients, and budgets efficiently. Understanding the costs of basement framing and insulation is very important to avoid financial shocks.

In this guide, we will break down the costs of framing and drywall insulation, helping you make a wise decision by addressing key concerns, providing practical examples, and offering a valuable cost breakdown to ensure your project is completed effectively and with the least budget overruns.

Understanding Framing Costs

Framing forms the structural skeleton of your basement, defining the walls, ceiling, and overall support systems. There are many factors that can impact basement framing costs, such as design, materials, and other features. However, understanding the specifics can help you set an accurate budget.

How Much Does it Cost to Frame walls in a basement?

The cost of basement framing can be estimated in several ways. Still, it's essential to remember that these averages are subject to fluctuations based on your location, labor rates, and specific project details.

- Per Linear Foot: $25 to $45 per linear foot for wooden studs and $30 to $55 per linear foot for metal studs.

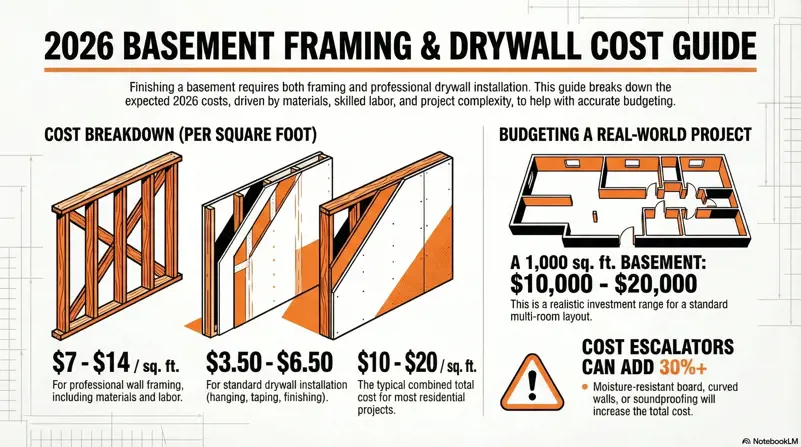

- Per Square Foot: $7 to $14 for basic wall framing and $9.00 to $16.00+ per square foot for complex framing.

For example, an 800-square-foot basement with 200 linear feet at $35 per linear foot would cost around $7,000 just for walls and $3,000 to $6,000 for ceiling framing.

Cost to Frame a Basement per Square Foot

Framing a basement involves several factors that directly influence the cost per square foot, including material choices, layout complexity, ceiling height, and local labor rates. In 2026, due to increased labor costs and material inflation, homeowners and contractors should expect the following averages:

- Wood Studs (Standard): $25–$45 per linear foot, which typically translates to $7–$14 per square foot of the total basement area for a complete professional installation.

- Metal Studs (Moisture-Resistant): $30–$55 per linear foot, or roughly $9–$16 per square foot. Metal is increasingly popular in 2026 for its mold resistance and durability in below-grade environments.

Example Calculation:

For a standard 1,000-square-foot basement with 8-foot walls and a basic layout, the framing investment (materials + labor) will realistically fall between $7,000 and $14,000. If your project includes intricate layouts, soffits for ductwork, or taller ceilings, expect a 25–40% increase in the total quote.

Why Precision Matters:

Understanding these 2026 market rates allows homeowners to budget effectively and helps contractors provide transparent, competitive bids. Using professional tools like the 247PRO Estimator ensures your quotes stay synchronized with local material prices and current labor trends.

Cost to frame and drywall basement

To achieve a fully finished and functional basement, framing is only the first step; professional drywall installation is essential to complete the shell. In 2026, the total cost is driven by high-efficiency materials, skilled labor rates, and the complexity of the basement layout.

Average Costs to frame and drywall basement in 2026:

- Wall Framing: As detailed previously, professional framing ranges from $7 to $14 per square foot (including materials and labor).

- Drywall Installation: Standard installation, including hanging, taping, and finishing (mudding/sanding), typically costs $3.50 to $6.50 per square foot of wall surface.

- Combined Total (Framing + Drywall): For most residential projects in 2026, the combined cost usually falls between $10 and $20 per square foot of the total basement area, depending on the number of interior walls and ceiling details.

Example Calculation:

For a 1,000-square-foot basement with a standard multi-room layout, the investment for both framing and drywall will realistically range from $10,000 to $20,000. Projects featuring moisture-resistant "purple board," curved architectural details, or soundproofing insulation can increase these costs by 30% or more.

Professional Budgeting:

Having a verified estimate for framing and drywall allows homeowners to secure financing with confidence and helps contractors maintain profitability. Using a construction invoice software along with a remodeling CRM can streamline billing, track payments, and manage project budgets, ensuring that both homeowners and contractors stay on time and within budget.

Labor Cost to Frame Basement Walls

Labor is often the most significant variable in a basement framing budget. labor rates reflect the high demand for skilled trades and the complexity of modern building codes. Labor costs are typically calculated per Linear Foot (LF) of wall rather than total square footage.

Average Labor Rates to Frame Basement Walls in 2026:

- Simple, Straight Walls: Approximately $15–$32 per linear foot. This covers standard wood or metal stud installation in open layouts.

- Complex or Curved Walls: Rates can jump to $35–$60 per linear foot. These projects require precision cutting, specialized tools, and significantly more time.

- Contractor Expertise: While master carpenters may charge 20-30% above market average, their efficiency and knowledge of 2026 structural codes often reduce long-term costs by preventing inspection failures.

Pro-Tip: Labor availability varies by region. To get the most accurate local rates, contractors use the 247PRO Estimator, which allows for localized labor rate adjustments, ensuring bids are both competitive and profitable.

How Much Does It Cost to Build a 2,000-Square-Foot Basement?

Building or finishing a 2,000-square-foot basement is a major investment. Costs are influenced by advanced moisture protection requirements, high-efficiency HVAC integration, and premium material trends. On average, homeowners should anticipate the following:

Cost Breakdown for 2026:

- Basic Framing and Drywall: $10–$18 per square foot. For a 2,000 sq. ft. space, this translates to $20,000–$36,000. This covers the structural skeleton and wall surfaces.

- Full Finishing (Turnkey Project): $35–$80 per square foot. This includes flooring, lighting, modern insulation, basic plumbing/fixtures, and painting.

- Total Project Investment: For a 2,000 sq. ft. basement, a full renovation typically ranges from $70,000 to $160,000.

Factors That Drive Costs Up (20-50% Increase):

- Sub-level Plumbing: Adding a bathroom or wet bar requires specialized pumping systems (Ejector pumps).

- Egress Windows: 2026 safety codes for large basements often require multiple emergency exits.

- Smart Integration: Built-in home theaters or automated climate zones.

Why Use Professional Tools?

Estimating a space this large manually is prone to errors. Contractors in 2026 rely on the 247PRO Estimator to ensure every linear foot of lumber and every sheet of drywall is accounted for based on current local market prices.

How Much Does It Cost to Frame a 1,000 sq. ft. Basement?

Framing a 1,000-square-foot basement is a standard renovation project. In 2026, the cost is largely determined by current material supply chain prices, localized skilled labor rates, wall layouts, and ceiling height codes.

Average Costs (Material & Labor Combined):

- Wood Studs: $7–$14 per square foot of the total basement area for basic wall framing.

- Metal Studs: $9–$16 per square foot, often used for enhanced moisture resistance and durability.

Example for a 1,000 sq. ft. Basement with Standard 8-foot Walls:

- Wall Framing Total: $7,000–$14,000

- Ceiling Framing (Soffits, Dropped Ceilings, Furring): $3,000–$6,000 (This varies heavily based on ductwork and plumbing coverage needed).

Additional Factors Increasing Cost:

- Complex or Multi-room Layouts: (+20–40% increase in total cost)

- Taller Ceilings (9ft+): (+15–25% increase due to specialized studs and labor)

- Complicated MEP Adjustments: Significant electrical or plumbing structural adjustments (MEP = Mechanical, Electrical, Plumbing) can add thousands to the framing budget.

Factors Significantly Impacting Framing Costs

Many factors can drive the cost to frame walls in a basement:

- Layout Complexity: Open layouts with fewer walls are generally less expensive, ranging from $7.00 to $14.00 per square foot. While multi-room designs will cost $14.00–$25.00 per sq ft. Due to more walls, more materials, and more openings.

- Wall Design: Walls usually come in two major designs: straight walls, which are typically cost-effective, and curved walls, which, due to the use of specialized materials, increased labor, and the need for bending, would add 20-50% to the final cost.

- Ceiling Height: Taller walls, measuring 9 to 10 ft., require longer studs and potentially more bracing, which can increase the cost by 15-25%.

- Existing Conditions: Any demolition, leveling of uneven floors, or work involving existing pipes or ductwork will add to the cost.

- Region: Each region can have its unique labor rate, mandatory permits, and special building codes.

Framing Materials: Wood vs. Metal Studs

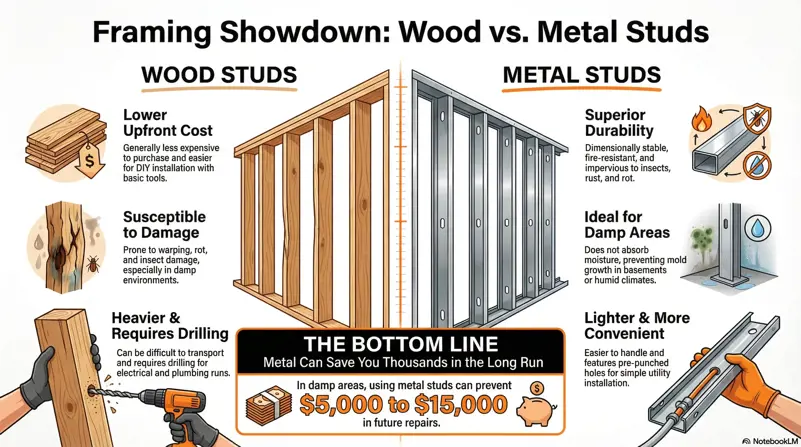

The choice of framing material impacts not only cost but also performance, durability, and ease of installation.

| Feature | Wood Studs | Metal Studs |

| Materials | Generally, less expensive upfront | Slightly more expensive upfront |

| Installation | Easier for DIYers, requires basic tools | Requires specialized tools |

| Durability | Prone to warping, shrinking, rot, and insect damage | Dimensionally stable, rust-resistant (galvanized), fire-resistant, no insect issues |

| Weight | Heavier items can be hard to transport and lift | Lighter, easier to handle, and transport |

| Soundproofing | Can transmit sound easily | Better sound-dampening properties |

| Moisture | Susceptible to mold and rot in a damp basement | Impervious to moisture, no mold growth |

| Electrical/Plumbing | Requires drilling holes (can weaken studs) | Pre-punched holes for easier wiring and plumbing runs |

| Fastening | Nails/screws for drywall, easier to hang items | Screws for drywall can be harder to hang heavy items without blocking |

As you can see, for basements prone to humidity, such as those in regions like Florida, metal studs are a better option in terms of mold and rot resistance. By doing so, you can save $5,000 to $15,000 in future repairs. You should also consider other factors, such as whether the materials are available in your region, how to schedule material delivery, and storage costs.

Additional Framing Needs

- Support for Heavy Fixtures: For TV mounts and shelves, you need additional reinforced framing, such as studs or blocking, to support the weight. This model costs around $1000 to $4,000.

- Pocket Doors: can add $800 to $2,500 per door due to specialized framing needs and hardware.

- Built-ins: Custom framing within the wall cavity is required for shelving or cabinets that can increase the cost by $2,000 to $8,000.

Deciphering Insulation Expenses

Insulation is critical for having a comfortable, energy-efficient, and moisture-controlled basement. However, the cost can vary widely based on material type and local requirements. Proper insulation can lead to significant long-term savings.

Types of Basement Insulation and Their Average Costs

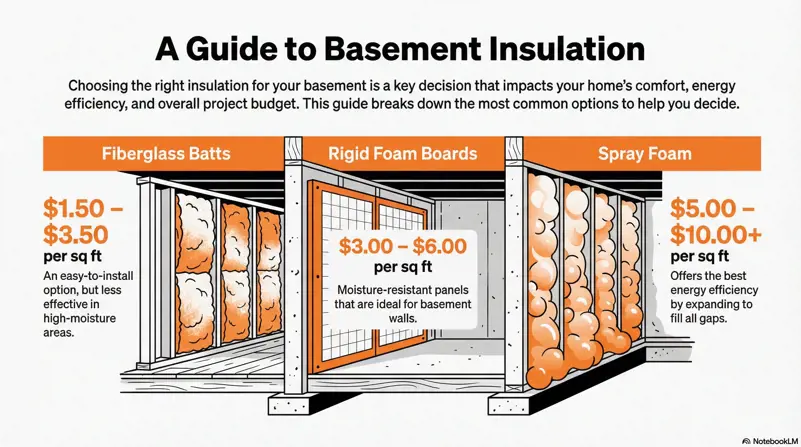

Choosing the right basement insulation affects comfort, energy efficiency, and costs. Here’s a quick overview of common types and their average price per square foot

| Insulation Type | Description | Average Cost (per sq ft) |

| Fiberglass Batts | Easy to install, made of glass fibers, less effective in high-moisture areas | $1.50 – $3.50 |

| Rigid Foam Boards | Polystyrene (XPS, EPS) or polyisocyanurate panels, moisture-resistant, ideal for basement walls | $3.00 – $6.00 |

| Spray Foam | Polyurethane foam sprayed as a liquid expands and hardens, making it best for energy efficiency | $5.00 – $10.00+ |

Which Insulation Type Provides the Best Value for Money?

- Spray Foam: Offers the highest insulation performance with an R-value of 6-7 per inch. It can act as a vapor barrier, resulting in a 30-50% reduction in energy bills ($1,000-$3,000+ per year, depending on home size and climate). Although the initial cost is high, it will result in significant long-term savings and often improves overall home energy ratings.

- Rigid Foam: Balances cost and performance with an R-value of 4-5 per inch. It is ideal for basements with moderate moisture issues and remains a popular middle-ground choice in 2026.

- Fiberglass: This is the most affordable option upfront; however, it requires an additional vapor barrier and pressure-treated framing, which can add $1,500 to $4,000 to the total project cost, and it’s less effective in humid climates like Florida.

R-Value Requirements and Cost Impact

Most building codes in the US require R-13 to R-19 for basement walls, and in colder states like Minnesota, R-15 to R-21 is recommended. Higher R-values typically indicate thicker insulation, multiple layers, or more expensive insulation types, such as spray foam. Check the local codes through the VAA lid and a trusted website or consult with construction project management firms.

Higher R-values can increase the cost by 10-20%. For example, upgrading from R-13 to R-19 with spray foam can add $800 to the final cost.

Moisture Control and Vapor Barriers

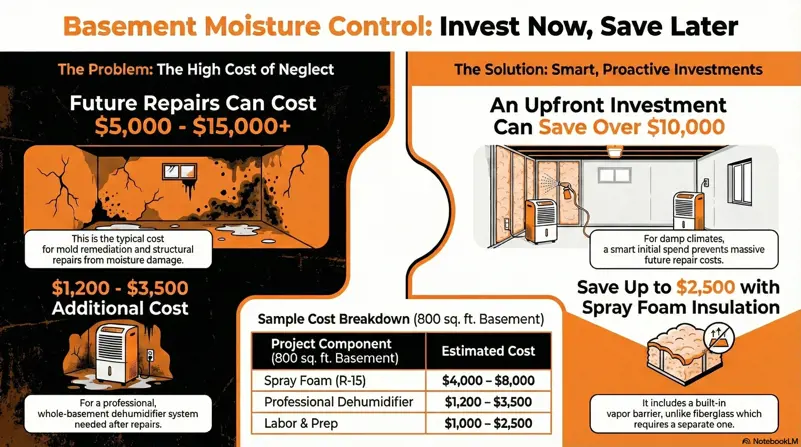

- Concrete: Basements are prone to moisture, so you need vapor barriers to resist the diffusion of moisture, which can cost $1.50 to $3.00 per square foot for high-performance 2026-grade materials.

- Solution: Spray foam includes a built-in vapor barrier that can save up to $2,500 in labor and material compared to fiberglass, which needs a separate barrier.

- Drainage and Waterproofing: Before any framing or insulation, ensure that your basement's exterior and interior waterproofing are in good condition.

- Hidden Cost: Failing to overcome structural issues can lead to mold remediation and repairs that cost $5,000 to $15,000+, with an additional $1,200 to $3,500 for a high-capacity, whole-basement dehumidifier system.

Here is an example of insulating an 800-square-foot basement in Seattle for a family room.

- Scope: Spray foam for walls, R-15, with a vapor barrier and dehumidifier.

- Total Cost: $6,800–$14,800

- Spray Foam (Installation & Material): $4,000–$8,000

- Dehumidifier (Professional Grade): $1,200–$3,500

- Labor & Prep: $1,000–$2,500

- Contingency (10%): $600–$800

Challenge: Due to the damp climate of Seattle, spray foam is required to prevent mold; this can add $3,000 to the initial budget but save over $10,000 in future remediation and structural repair costs.

Beyond the Basics: Hidden & Related Costs

Basement renovation often involves hidden costs, such as waterproofing and permitting, as well as unexpected issues that can quickly and significantly impact the budget. Understanding these costs and preparing to prevent and overcome them can help avoid major financial surprises. Along with using a remodeling CRM and construction invoice software, integrating a construction text messaging app ensures real-time updates, reduces miscommunication, and prevents costly mistakes. For a more comprehensive and detailed exploration of these expenses, we highly recommend reading "The Ultimate Guide to Basement & Garage Finishing Costs" to ensure you account for all potential surprises.

Garage renovation can also be tricky when it comes to hidden costs; the mentioned article can help you use a garage construction cost estimator to predict and overcome these costs.

Value & ROI

Finishing your basement is an investment that can significantly improve your home's value by 50–75% of the renovation cost. A well-framed and insulated basement, which might cost $45,000 to $85,000 to renovate in 2026, can add a $25,000–$60,000 value increase to your property. Converting the basement to a living space, such as a bedroom, can further boost ROI, but ensure it is in accordance with local 2026 egress and safety codes.

High-performance insulation, such as spray foam, can reduce energy consumption by 30–50%. This means the initial investment can typically be fully recovered within 4 to 6 years due to rising utility costs. You can use the building construction cost calculator to estimate potential savings based on your location and 2026 energy rates.

FAQ

1. Can I frame my basement myself, or do I need to hire a contractor?

If you have experience with wood or metal framing and construction tools, you can DIY part of the project and save on costs. However, for complex ceilings, curved walls, or compliance with local codes (like ceiling height and permits), hiring a professional contractor is recommended to avoid costly mistakes and inspection issues.

2.What’s the best way to manage costs and avoid hidden expenses?

Using tools like a remodeling CRM, construction invoice software, and a construction text messaging app together can help you track your project, manage invoices, and maintain clear communication with contractors and teams, keeping the project on schedule and on budget.

3.Which type of insulation is best for a humid basement?

- Spray Foam: Offers the highest thermal performance and moisture resistance, reducing energy bills by 30–50%.

- Rigid Foam: A middle-ground option for moderate humidity areas.

- Fiberglass: Cheapest upfront, but requires a separate vapor barrier and is less effective in very humid regions.

4. Is metal framing better than wood framing?

- Metal Studs are ideal for humid regions (like Florida) because they resist mold and rot.

- Wood Studs are cheaper but can warp, shrink, or be damaged by insects over time.

5. How can I estimate costs based on basement size?

- 1,000 sq. ft. basement: Framing + drywall costs $10,000–$20,000

- 2,000 sq. ft. basement: Framing + drywall costs $20,000–$36,000

- Using tools like 247PRO Estimator or similar helps provide accurate estimates based on local labor rates and material costs.

6. What additional features or upgrades can increase project costs?

- High or curved ceilings, multi-room layouts

- Pocket doors or built-in shelving/cabinets

- Reinforced framing for heavy fixtures like TVs or shelving

- Adding a bathroom or wet bar

- These upgrades can increase the total project cost by 10–50%.

7. What’s the return on investment (ROI) for a basement remodel?

A well-framed and insulated basement can increase home value by 50–75% of the renovation cost.

High-performance insulation like spray foam can reduce energy costs by 30–50%, potentially paying back the initial investment within 4–6 years.