One of the important points you need to have in mind while using a metal building cost calculator is navigating legal and contractual complexities to ensure project success. Stepping into the legal and contractual aspects of a construction project can feel like entering a maze. Many homeowners and contractors often overlook crucial details about permits, certifications, and hidden costs.

We are going to break down the must-know legal and contractual considerations you need to know for your steel structure projects. Understanding these legal games are parts of the ultimate guide to steel building cost estimation we can provide in 247pro, which can help you protect your investment.

Common contract types in steel projects

Understanding the type of contracts used in steel projects is essential for estimating the cost of your projects. Here are some of the most common contracts you need to know:

Trunky or Lump Sum Contract

In these contracts, both sides agree to build the project for a fixed price, which is set upfront. This price includes the costs of materials, labor, design, and construction.

Through this contract, owners will have minimal involvement in the process and will have a very clear and detailed bid from the start. These contracts are ideal for pre-engineered metal buildings (PEMB), where the design is straightforward and largely follows standard procedures. However, you should note that these contracts are less flexible in case you want to make some changes mid-project.

Unit Price Contract

In such contracts, the costs are based on specific quantities or units, for example, a price per ton of steel or a price per square foot. The total bill will be calculated by multiplying the unit price by the actual quantities used during construction. They are flexible for projects with uncertain scopes. However, there is always the risk of cost overruns if the quantities exceed estimates.

Cost-Plus or Time & Material Contract

In these types of contracts, the owner agrees to pay for all project costs, including materials, as well as an agreed-upon fee for the contractor's profit. This is the most flexible type of contract for design changes during the project and is best for customized steel projects with complex designs. However, the problem with such contracts is that the total cost is largely unknown and requires a high level of trust from the owners.

The importance of detail in contracts

The contract isn't just a piece of paper; it's the project's rulebook. The clearer and more detailed your contract is, regardless of its type, the fewer problems you will face in the future. Key elements in all types of contracts are as follows:

- Precise Scope of Work: The contract must define exactly what the contractor is building, supplying, and installing. For example:

- Type and grade of steel

- Detailed design

- Different types of inclusions

- Erection

- Any specific finishes and coatings

- Timeline: Clearly specifies project start and completion dates, including milestones such as foundation completion or steel erection. Additionally, you can include penalties for delays, such as $300 per day for any delay beyond the deadline.

- Quality standards define the exact quality of the materials, fabrication, and installation. It usually requires third-party inspections to verify quality, which can cost between $1,000 and $3,000.

- Payment terms: This includes a payment schedule tied to milestones, such as 30% upon steel delivery, 50% upon completion, and retainage

- Permits and Compliance: clarify who is responsible for obtaining the mandatory permits, the homeowner or the contractor, and ensure they are in accordance with local codes

How to manage project changes (change orders) to prevent cost overruns

Change is inevitable even in the most detailed contracts. Changes are the leading cause of cost overruns and disputes in most steel projects. The main reasons for these changes are:

- Design evolution

- Unforeseen site conditions

- Material availability

- Code updates

When a change occurs, you must follow a process to minimize budget pitfalls. For contractors, it is recommended to document a written request and provide a clear estimate of how the change will impact the project's cost and timeline. The final step is to obtain the owner's written approval. You should never agree to a project change verbally; without written documentation, some serious problems might happen. Homeowners should also track the changes; using construction project tracking software can help monitor change orders.

The best way to manage project changes is to minimize them by conducting thorough and complete designs before construction and performing precise site assessments and soil tests to avoid surprises.

State-specific considerations are another crucial step in managing project changes; some states, such as California, require higher-quality materials due to seismic conditions.

Key considerations for selecting contractors and overseeing execution

Choosing the proper contractor for your steel building project is crucial to ensure that the project is completed within the agreed-upon time and budget, which significantly impacts your project's success. Tips that you need to know while choosing a contractor are as follows:

- Their experience with steel: look for contractors with good reputations in steel building construction; Ask for references from similar projects.

- Licensing and Insurance: Verifying the contractor's license in your state and having adequate liability insurance to cover unexpected damages, as well as Workers' Compensation insurance, is an important pre-construction step. These licensed requirements might vary significantly from one region to another

- References and Reputation: Contact their former clients and ask for their feedback. Ask about how the contractors stuck to the budget and schedule, the quality of their work, and how they managed unexpected issues.

- Clear Communication: The right contractor always communicates clearly, frequently, and actively.

- Use of technology: Ask what tools they usually use to manage projects. Many professionals utilize metal building cost calculators or tracking software to monitor project progress, manage documents, and track expenses against the budget.

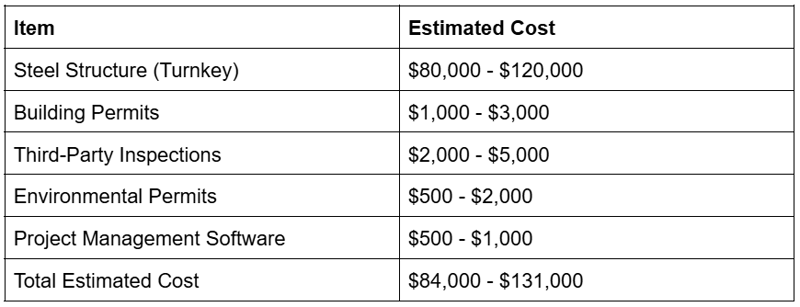

Example: Cost Breakdown for a 1,000-Square-Foot Steel Building

Here, we have provided a sample cost breakdown for a 1,000-square-foot commercial steel structure in San Francisco under a turnkey contract to examine the permits and oversight costs:

As mentioned earlier, these numbers may vary from one state to another, depending on their geographical characteristics. San Francisco, for example, has high labor ($30-$40/hour) and material costs, and due to DBI's seismic and safety plan, building permits will cost more