Construction has been an essential part of society since the dawn of civilization, but modern technology has completely changed the industry over the last few decades.The impact of technology in the construction industry is evident in areas such as efficiency, safety, and productivity.

From drones to robotics, construction processes are becoming more efficient, faster, and safer than ever.

This change in how things are made may be relatively new, but it's sure to stick around for years.

Let's look at some of the biggest ways technology has impacted the construction industry and where it might be headed in the future.

How does technology affect the construction industry?

Technology has fundamentally transformed the construction industry over the past few decades. From planning and design to execution and project management, modern tools and digital solutions have changed how work is done, improving efficiency, safety, and overall project quality. These technological advancements not only streamline operations but also help construction companies respond more effectively to the growing demands and complex challenges of modern projects.

Digital transformation in the construction industry

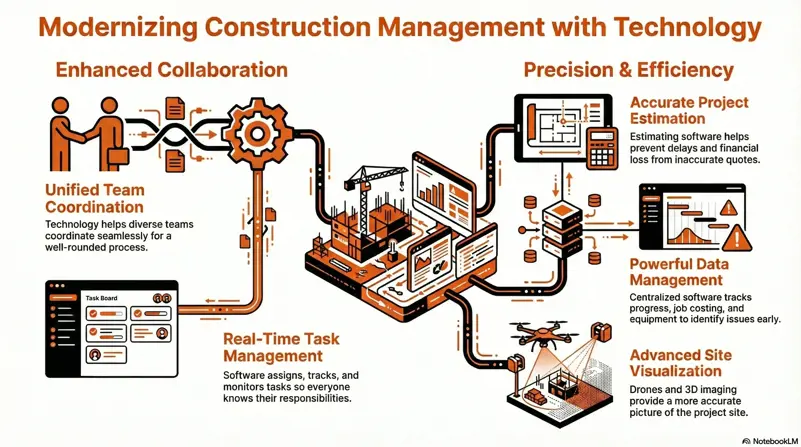

Digital transformation involves integrating digital technologies into every aspect of construction operations. This includes the adoption of construction management software, cloud-based collaboration platforms, and data-driven decision-making processes. By digitizing workflows and automating routine tasks, companies can reduce errors, improve communication between teams, and ensure better project oversight.

Tools such as construction change order management software allow teams to efficiently track, approve, and implement project modifications, ensuring updates are reflected in schedules, budgets, and resources in real-time. Technologies like Building Information Modeling (BIM), drones, and AI-driven analytics are at the forefront of this transformation, enabling construction firms to plan, monitor, and execute projects more efficiently than ever before.

Positive impact of technology on construction industry

Technology has significantly improved the construction industry across multiple areas. Here are some of the key construction technology positive impacts observed in modern projects:

- Increased Productivity: Automated machinery, drones, and GPS-guided equipment help workers complete tasks faster, reducing project timelines and costs.

- Modular Construction: Prefabrication and off-site construction speed up assembly while ensuring precision.

- Artificial Intelligence: AI monitors workflows, predicts delays, tracks inventory, and optimizes project performance.

- Enhanced Collaboration: Digital platforms keep teams, contractors, and suppliers aligned, reducing errors and miscommunication.

- Advanced Software & Estimation Tools: Tools like 247PRO improve cost estimation, labor management, and project tracking.

- Increased Safety: Wearable devices and on-site sensors monitor worker health and environmental conditions, preventing accidents.

- Addressing Labor Shortages: Robotics and autonomous equipment supplement human labor for repetitive or hazardous tasks.

- Efficient Financial Management: Invoicing software for contractors helps automate billing, track payments, and ensure accurate project accounting.

Increased Productivity

Construction projects are always different from each other and even from day to day depending on weather or other circumstances at job sites, but thanks to technological advances, it has become easier than ever before because people can do tasks faster and more efficiently than ever before which then translates into less time required.

With the help of drones, 3D printing, and GPS-guided machinery, construction workers can do more in less time. Additionally, remodeling estimating software streamlines planning for renovation projects, allowing teams to calculate costs quickly and allocate resources efficiently, further boosting productivity.

This saves the contractor money and means that projects can be completed faster, which is excellent for customers.

When there is an obvious lack of productivity about the rising demand for construction, issues such as delayed completion start arising, and new technology has proven critical for the industry; it helps cut down on delays because it can't be made into a generic one size fits all process.

Modular Construction

Building the way we do now is no longer enough; construction needs to be done as quickly and efficiently as possible.

Many ways of doing this, including prefabrication and off-site construction, help make the process easier.

Prefabricated buildings consist of parts built elsewhere before being brought together at the site;this saves valuable time.

This method has been around for a while, but 3D printing techniques for prefabrication are entirely new to the industry. With these techniques, you can program exactly what shape or size you need from something like cements, metals, or plastics.

Once everything cools down, it hardens and can be used for whatever purpose was desired beforehand. Off-site construction can be done both with modularity or prefabricates.

Modular construction entails constructing an entire room out of the correct fixtures and fittings, usually done when building large apartment complexes or hotels.

With prefabrication, important components such as framing, internal and external wall panels, doors, and windows are put together off-site before being assembled at their designated locations where they make sense.

Artificial Intelligence

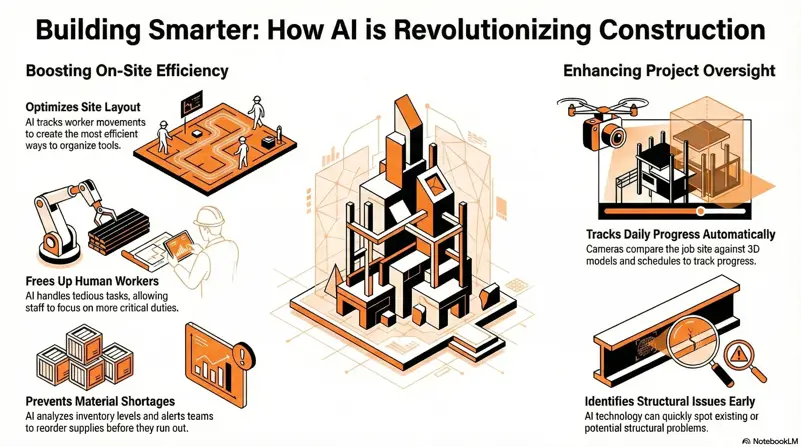

AI and machine learning systems are becoming increasingly prevalent in construction fields.

Productivity is significantly boosted for sites that adopt these technologies because they can handle specific tasks that would otherwise require a human to complete.

By utilizing them, humans can focus on more pressing matters on the job site without being constrained by tedious tasks,allocating their time wisely. One of the most significant things these technologies allow humans to do is track how much time one spends moving around the site.

As one executes their duties, AI systems can track actions such as retrieving tools, materials, and other equipment.

These datasets could then be analyzed so you may create a list of optimal ways to store and organize items, decreasing the time it takes per day while complete an action.

AIs can also help in monitoring projects' progression.

Utilizing cameras to document every step of the project and then comparing them against BIM models, 3D drawings, and construction schedules lets us know how much progress has been made each day.

Not only can they track performance, but AI techs can also quickly spot any structural issues you might have already faced or could face in the future. Productivity largely relies on a reliable supply chain which any construction site depends on for its success,running out of key supplies will significantly slow work down and push back completion dates.

AIs can analyze relevant data points like inventory levels and just how fast resources are being depleted; this information helps ensure that we never run out of essentials by alerting workers when it's time to reorder before stocks completely deplete.

Easy Project Collaboration

Collaboration is a valuable part of almost any company, including construction.

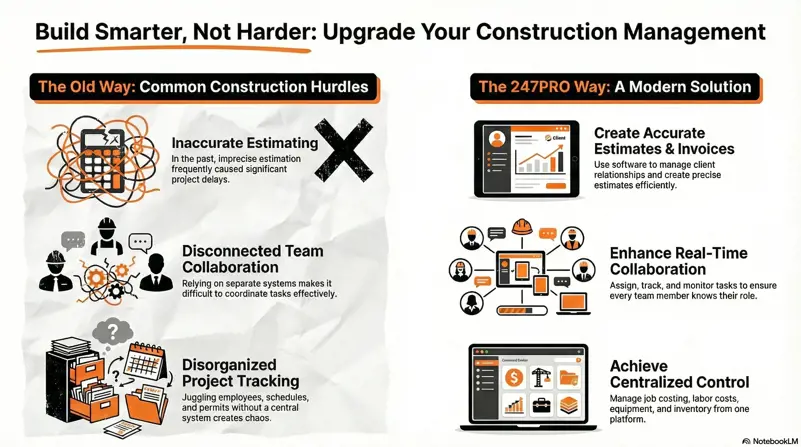

Many players in the construction industry rely on each other to complete projects, and technologies exist to help these workers coordinate with one another for a well-rounded process. Construction work order management software further enhances collaboration by assigning, tracking, and monitoring tasks in real-time, ensuring that each team member knows their responsibilities and deadlines.

Technology and Estimation Software

Technology has helped contractors become more efficient and accurate in their work in today's construction industry.

In the past, construction projects were often delayed due to inaccurate estimation.

Using estimating software like 247PRO or remodeling CRM systems can help you manage client relationships, create accurate estimates, and send invoices easily and efficiently.

Maintaining an organized construction project is key to successful management.

There are many things to keep track of, including employees, schedules, permits, etc.

This has helped to reduce delays and increase safety. Additionally, data management has become easier with new software that can help track progress and identify potential issues.

247PRO software helps manage millions of data points and records by providing labor costs, job costing, project management, equipment and inventory management, etc.

Since these software offer so many benefits and are crucial in the construction industry,they can be beneficial for those in the construction industry who rely on multiple programs when dealing with projects.

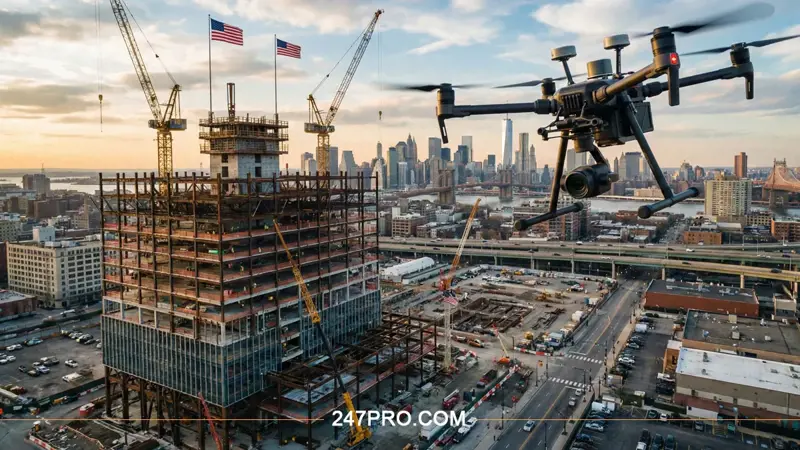

Moreover, with new technology, such as drones and 3D imaging, contractors can now get a more accurate picture of a project site.

Increased Safety

Preventing work accidents that lead to severe injury or death should always be a priority in the construction industry.

Safety for everyone involved is paramount, and thanks to technology, job sites are much safer now than ever before.

Increased safety is one of technology's most significant impacts on the construction industry.

With new safety features and data management capabilities, construction workers can avoid accidents and injuries.

By formalizing safety protocols and procedures, construction companies can create a safer work environment for their employees.

Proper safety and equipment operation training is one of the most crucial components of any construction project.

To keep workers safe, they must understand how to carry out each task correctly.

Training also becomes challenging because it poses risks, even if you're already an expert at completing tasks on a job site.

Wearable Technology

When it comes to personal protection equipment required on construction sites, most people think of hard hats, gloves, and good work boots.

But there's so much more that goes into keeping workers safe during every construction process.

Many construction sites have integrated all sorts of 'wearable' technology. Think about biometrics or environmental sensors, for starters!

Those systems monitor worker movement and warn when we're about to do something dangerous, like enter restricted areas set up via geofencing software which operates through audio alarms and visual alerts when you get too close to one of those spaces defined beforehand.

Technology has given us new ways to monitor construction workers' physical health closely.

So-called smart clothing can monitor a worker's heart rate and breathing pattern to track any abnormalities in their postures or movements.

By doing so, they can assess whether or not the worker can complete tasks at hand, no matter how difficult they may be.

On-site Sensors

Construction sites are filled with various different types of dangers. Extremely high noise levels, high temperatures, large amounts of dust and dirt, and volatile substances risk continuously exposed workers.

Specific sensors can be mounted on site, so environments are closely monitored for safe working conditions.

If any levels get too high, work stoppage begins immediately to avoid putting lives at further risk.

Reducing Labor Shortages

In recent years, the construction industry has been met with several struggles as they cannot find sufficient workers to complete the increasing number of jobs.

Newer entrants into this field tend to lack the knowledge or experience that their predecessors had, making it increasingly difficult for businesses needing these skillsets like welding or concrete placement.

With people retiring and children taking jobs outside of this sector, it's hard not to notice that significantly fewer people want jobs in construction today than before. Construction text messaging apps help mitigate these challenges by enabling efficient communication between limited teams, ensuring that task assignments, updates, and urgent instructions reach everyone quickly.

Robots and Drones in Construction: A 2026 Overview

When humans cannot provide adequate labor, automation and machinery become necessary.

Robots can perform tedious and time-consuming jobs, such as laying bricks or tying steel bars, twice as fast without getting tired as humans would after completing this type of work for hours.

Robots can't function properly unless someone is supervising them at all times. However, they provide a valuable resource for organizations since professionals are needed to ensure everything runs smoothly, stopping potential mishaps before they escalate.

Robots' assistance makes construction tasks more manageable and allows workers to finish projects faster than other methods.

Drones have also been put to work in the construction industry.

For hazardous tasks, such as inspecting high-rise buildings or construction sites, drones offer a close-up view for workers on the ground, who will remain safe from harm.

Drones are helpful even when photographing projects from overhead; they allow us to track where we've come from and where we're going, thereby enhancing safety precautions and getting all parties involved up-to-date with new perspectives (and therefore better informed).

Terrestrial drones are helpful for many different tasks on the ground. Terrestrial drones can collect information from all over a job site property by utilizing their unique functions such as light detection, range scanning data, and sensors.

Heavy Equipment Operation

While some jobs are impossible to automate entirely due to human limitations, autonomous equipment can be utilized to make specific tasks easier.

For example, this innovation in the construction industry makes it so workers don't need to perform strenuous labor instead, they can focus on other aspects of projects.

This is especially useful when there is a workforce shortage for specific tasks or increased workloads.

Autonomous heavy equipment moves along its assigned path without requiring human input using a mix of sensors, drones, GPS, and 3D models.

This system saves time and money while ensuring worker safety thanks to geofencing alerts when an individual strays too close to an area that needs work.

Furthermore, this technique can also contain the movement of these vehicles to only those areas where necessary without entering others that may pose hazards.

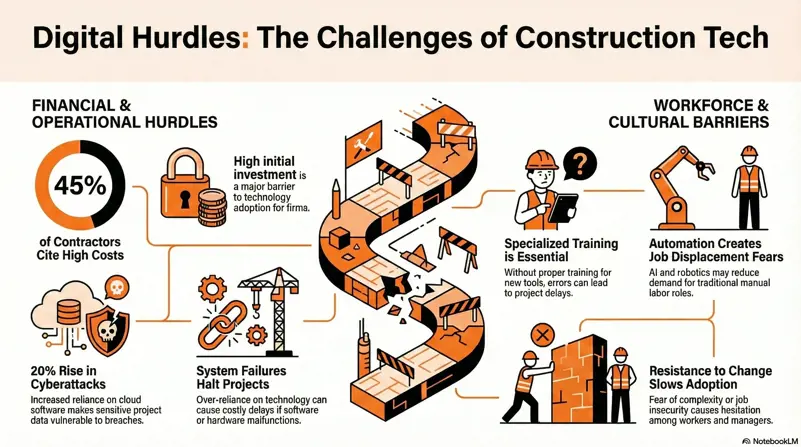

Negative impact of technology on construction industry

While technology brings immense benefits to the construction industry, there are several challenges and drawbacks that must be carefully considered:

- High implementation costs: Implementing advanced technologies like robotics, AI, and autonomous machinery requires significant upfront investment. Small and mid-sized construction firms often face budget constraints, making it difficult to adopt these innovations. According to a 2025 industry survey, nearly 45% of contractors cited high initial costs as a major barrier to technology adoption.

- Need for specialized training: Modern construction technologies require skilled operators and technicians. Workers must be trained to handle AI systems, drones, 3D printing, and digital management platforms. Without proper training, errors can occur, leading to project delays and cost overruns. Many companies now invest in continuous professional development programs to ensure staff can effectively use new tools.

- Data security and privacy risks: As construction sites rely more on cloud-based software, BIM models, and IoT-enabled sensors, sensitive project data becomes vulnerable to cyberattacks. Breaches can expose proprietary designs, financial information, or client data. Recent reports indicate a 20% increase in cyber incidents targeting construction firms between 2023–2025. Companies must implement robust cybersecurity protocols to protect data.

- Dependence on technology and system failures: Heavy reliance on software, automated machinery, or drones can pose risks if systems malfunction. Power outages, software bugs, or hardware failures can halt projects, causing delays and financial losses. Backup systems, redundancy planning, and regular maintenance are essential to mitigate these risks.

- Job displacement concerns: Automation and AI can replace repetitive or manual tasks, which raises concerns about workforce displacement. While technology increases efficiency, it may reduce demand for traditional roles such as bricklaying, surveying, or manual labor. The industry needs strategies for reskilling employees and integrating human expertise with automated processes.

- Resistance to change: Many construction workers and managers are hesitant to adopt new technologies due to fear of complexity or job insecurity. This resistance can slow down digital transformation efforts, even when the tools are proven to improve efficiency. Change management strategies, workshops, and pilot programs can help overcome these barriers.

What type of technology is used in construction?

Key technologies commonly used in modern construction include:

- Construction management software

- Automation and robotics

- Artificial intelligence and machine learning

- Wearable and sensor-based technologies

- Drones and imaging technologies

10 examples of construction technology

- Drones

- Artificial Intelligence (AI)

- Modular construction

- Estimation software (e.g., 247PRO)

- Wearable safety technology

- On-site environmental sensors

- Construction robots

- Autonomous heavy equipment

- 3D printing technology

- BIM (Building Information Modeling) and digital project management tools

What are the latest technologies in the construction industry?

Recent trends transforming construction include:

- Digital twins

- AI-powered project forecasting

- Autonomous construction equipment

- Advanced BIM integration

- 3D printing in large-scale construction

Conclusion

While technology has changed the construction industry several ways, safety and data management have had the most significant impacts. Construction workers can now use GPS systems to track their location, which has made worksites much safer.

In addition, new software programs have been developed that help construction managers keep track of project progress and budgeting. Understanding the impact of technology on the construction industry is crucial as companies continue to adopt new tools for efficiency and safety.

As construction companies adopt new technologies, we expect even more changes in how projects are planned, managed, and executed.

FAQ

How can the cost of installing and maintaining smart equipment on construction sites be optimized?

By analyzing equipment performance data, using predictive maintenance services, and prioritizing essential equipment purchases, overall costs can be reduced

Does using AI in construction increase human error or reduce it?

AI generally reduces human errors by monitoring tasks and providing instant alerts. However, human supervision is still essential for final decision-making.

What criteria should be considered when choosing the right project management software?

Key criteria include task and progress tracking, integration with financial software, ease of team access, accurate reporting, and data security.

Can new technologies help reduce material waste in construction projects?

Yes. Using BIM and inventory management software can significantly reduce material waste and enable more precise project planning.

How can data from sensors and wearable devices improve worker safety?

Health and environmental data can identify risk patterns, trigger instant alerts to prevent accidents, and serve as practical training resources.

How can new technologies help address labor shortages in construction?

Robots, autonomous machinery, and automation software can handle repetitive or hazardous tasks, allowing human workers to focus on more complex responsibilities.

What are the main barriers to adopting advanced technologies in small and medium construction companies?

Main barriers include high upfront costs, the need for specialized training, employee resistance to change, and data security concerns. Solutions include phased budgeting and continuous training programs.