Commercial and office buildings, unlike residential and industrial buildings, require flexibility and openness in addition to being strong and durable. Steel is one of the materials that provide these options due to its fast erection time, resistance to heavy loads, and its environmentally friendly characteristics.

You can always use a valid steel building cost calculator to estimate the cost of steel structures for commercial and office buildings; however, estimating the cost of these structures can be more complex than other types of buildings. We will now introduce the key factors that influence the cost, as well as some technical and architectural details that shape the final price.

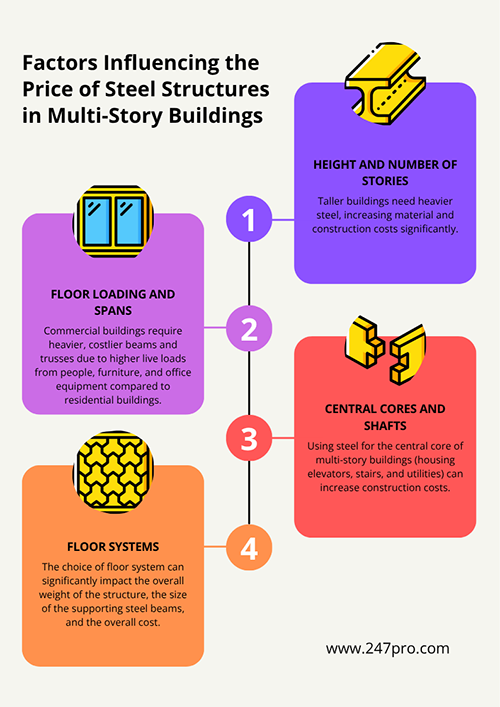

Factors Influencing the Price of Steel Structures in Multi-Story Buildings

Multi-story buildings, especially commercial and office buildings, have some unique designs and complexities that directly impact the cost of steel structures. Some of them are as follows:

- Height and Number of Stories: Taller buildings require stronger columns and beams to support the heavy load; therefore, heavier steel types should be used in such buildings. The high tonnage of steel and equipment required for erecting steel at higher elevations will all add to your cost.

- Floor Loading and Spans: Unlike residential buildings, commercial buildings typically have higher live loads, which means that the weight of people, furniture, and office equipment requires heavier and more expensive beams and trusses.

- Central Cores and Shafts: Multi-story buildings have a central core designed for elevators, stairwells, and utility shafts, such as HVAC systems and electrical risers. Using steel to design and construct these cores can increase the cost.

- Floor Systems: The choice of floor system can significantly impact the overall weight of the structure, the size of the supporting steel beams, and the overall cost.

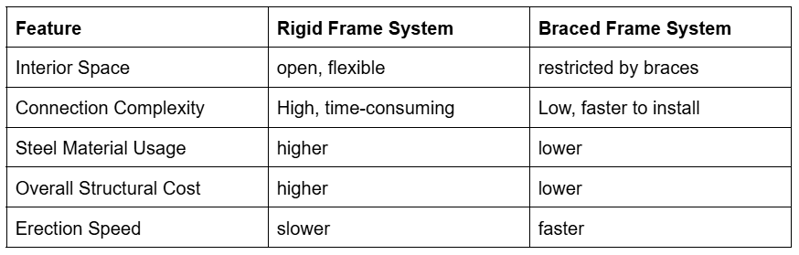

Comparison of rigid frame and braced frame systems

Steel structure buildings typically use one of two structural systems: a rigid frame or a braced frame system. Selecting each system can play a crucial role in cost and seismic performance. These two systems include:

Rigid Frame System

In this system, connections between beams and columns are designed to transfer bending forces, enhancing the structure’s stiffness and ensuring lateral stability against wind and seismic loads.

- Advantages: This system provides more open space inside the building, eliminating the need for diagonal bracing, which can restrict architectural layouts.

- Disadvantages: On the other hand, this system is expensive and more complex; additionally, it will require more materials to erect, which necessitates heavier steel sections.

Braced Frame System

The braced frame system provides stability by diagonal bracing installed between beams and columns, mainly arranged in X, V, or K configurations. In comparison to other systems, the connection between beams and columns is much simpler.

- Advantages: The buildings constructed by this system are much lighter and more economical in terms of materials. Also, it is easier to erect.

- Disadvantages: Braces will take up much space and might limit the architectural flexibility and window placements.

In the table below, you can simply compare these steel structural systems.

Costs Related to Building Facades and Architectural Details in Steel Structures

Building’s exterior facade and architectural details, especially in commercial or office buildings, apart from an aesthetic appeal, can significantly influence the overall cost of steel structures:

- The choice of facade materials can impact he type and the amount of steel that is needed for its attachment to the main structure. All can affect the final cost. For example, glass curtain walls will cost $50 to $100 per square foot, metal panels will cost $20 to $40 per square foot, or brick cladding’s cost will range from $30 to $60 per square foot.

- Architectural Details: Customized elements, such as decorative steel beams, protrusions, recesses, and curved forms, will require additional steel and more complex designs.

- Large Facade Openings: Having large openings for windows or entrances requires stronger supporting beams, which can be costly.

- Facade Load Bearing: The facade must be supported by a steel structure to withstand wind and weight loads. The heavier the facades are, the stronger the columns and beams will need to be.

- Installation Complexity: Complex facades and architectural details will require skilled specialists and labor as well as specialized equipment to install.

The Importance of Seismic Calculations and Their Impact on Steel Weight

In many regions of the country, such as California, which are in seismic zones, seismic calculations are a crucial aspect of steel structure design to ensure safety and stability. Earthquakes can impose significant forces on buildings, so the structure must be able to absorb or resist them.

Buildings in high-seismic zones will need additional steel reinforcement to neutralize the lateral force. This will impact the steel’s weight and cost.

- To resist seismic forces, the building requires stronger columns, beams, and connections. This can increase steel usage by 10-30%, depending on the scope and location of the building. For example, a 1,000-square-foot building in a high-seismic zone in California might need an additional 1 to 2.5 tons of steel.

- Seismic design will require high expertise from the structural engineer and will take more time for planning and detailing, which can lead to higher engineering fees.

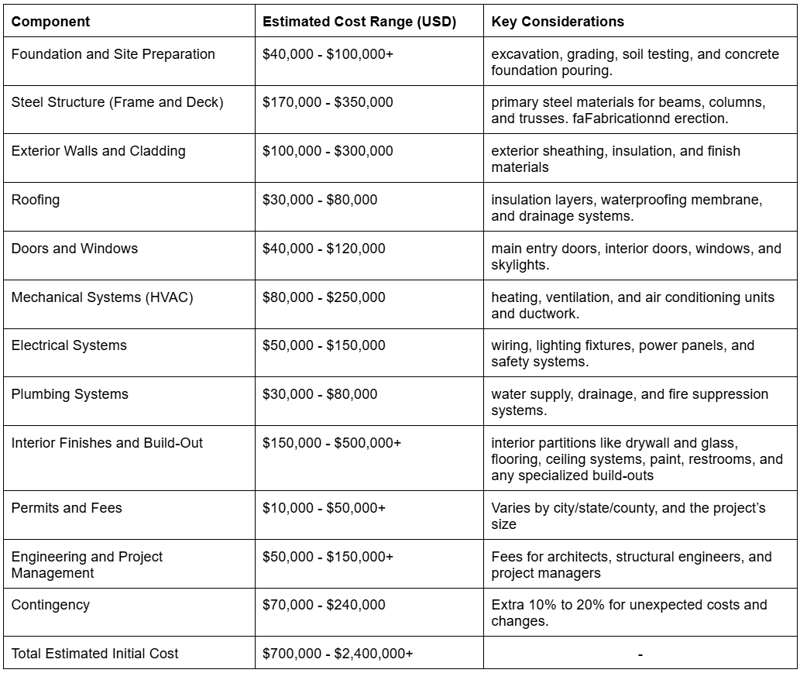

Estimating Costs: Example of a 10,000 Square Foot Commercial Building

For estimating the cost of steel structures for commercial and office buildings, it would be easier to take a 10,000 square foot commercial or office building as an example and break it down to its components to have a better understanding of the costs.

These are just the preliminary estimates. For more precise quotation, you can use The Ultimate Guide to Steel Building Cost Estimation methods, or you can get help from construction project management firms to calculate the cost of the project based on your project's unique principles.